Cost Effective Utilization of Poultry and Cruciferous Vegetable Waste as a Raw Material to Develop a Shelf-stable Pet Food

N Brindha, V Appa Rao

DOI10.21767/2572-5459.100027

N Brindha* and V Appa Rao

Department of Livestock Product technology, Madras Veterinary College, Chennai, Tamil Nadu, India

- Corresponding Author:

- Brindha N

Department of Livestock Product technology

Madras Veterinary College, Chennai, 600 007, Tamil Nadu, India

Tel: 91 9790795975

E-mail: brindha26887@gmail.com

Received Date: January 17, 2017; Accepted Date: May 27, 2017; Published Date: May 30, 2017

Citation: Brindha N, Rao VA. Cost Effective Utilization of Poultry and Cruciferous Vegetable Waste as a Raw Material to Develop a Shelf-stable Pet Food. J Anim Res Nutr 2017, 2:7. doi: 10.21767/2572-5459.100027

Copyright: © 2017 Brindha N. This is an open-access article distributed under the terms of the Creative Commons Attribution License, which permits unrestricted use, distribution, and reproduction in any medium, provided the original author and source are credited.

Abstract

To develop a pet food with the incorporation of 35% and 10% poultry and cruciferous by product meal and to evaluate the nutritive composition and shelf-life of the prepared product. The proximate composition of the pet food as feed basis for moisture, crude protein, ether extract, crude fibre, total ash, nitrogen free extract and metabolizable energy were 4.57%, 25.41%, 17.68%, 1.32%, 9.82%, 45.77% and 420.15 kcal/100 g, respectively. The proximate composition of pet food on dry matter basis for crude protein, ether extract, crude fiber, total ash, nitrogen free extract and metabolizable energy were 26.63%, 18.52%, 1.38%, 10.29%, 43.17% and 422.28 kcal/100 g, respectively. The thiobarbituric acid value, tyrosine value and total viable count of the prepared pet food was in increasing trend and yeast and mould count could not be detected up to 50 days of storage period. The pet acceptability studies also revealed acceptability of the pet food by pets. The cost of production of pet food is Rs.70/kg.

Keywords

Petfood; Poultry byproduct meal; Cruciferous vegetable byproduct meal

Introduction

Pets play a vital role in the day to day activities and act as a family member both in urban and rural areas. Feeding of pet dogs was very composite in the previous years due to unavailability of a complete balanced nutritious food. Due to rapid urbanization and globalization along with foreign collaborative partnership, pet food industry has attempted to produce nutritionally balanced pet foods to meet the nutritional demand of pet dogs. Poultry offal consists of head, feet and inedible viscera. It is mainly used in preparation of pet food, in fish hatcheries, hog food preparation and used as meat scrap for poultry and other livestock feed manufacturing [1]. Poultry protein meals are a popular high quality protein source used in pet foods. The pet food industry consumes an estimated 23% of the rendered poultry proteins produced each year [2]. Najafabadi et al. conducted proximate analysis of poultry byproduct meal and reported that the dry matter, ether extract, crude protein, crude fibre and ash contents were 94.8, 23.4, 60.5, 0.90, and 9.3%, respectively. The average gross energy value for the poultry by-product meal was 5645 kcal kg-1 [3]. The calcium, phosphorous, sodium, potassium, chloride, magnesium, and sulphur contents were 3.51, 1.88, 0.52, 0.31, 0.74, 0.06, and 0.99% respectively, while the contents of iron, copper, manganese, zinc, and selenium were 623.2, 9.3, 16.5, 47.8 and 0.73 mg kg-1 respectively.

Non utilization of animal by-product would create major aesthetic and hazardous public health problem. The effective utilization of animal by-products and water and sewage treatment plants undoubtedly has a major influence in upgrading public health. [4].

The pet food chain is a complex network, involving various industries. The current carbon and water footprint estimates for dietary ingredients are useful to some extent as they pertain to pet foods, but only if the ingredients are suitable for human consumption and are directly competing with the human food system. In recent years, the use of human-grade ingredients has been suggested in homemade and commercial diets. For the majority of diets in the pet food industry that are based largely on human food by-products, however, such estimates may have limited use. Hundreds of human food by-products are currently available and used by the pet food industry. Rather than competing with humans for food, pet foods based on byproducts actually lighten the environmental burden of the human food system.

In India, chicken meat consumption forms a major share in the population owing to its reduced cost and consumer preference when compared to other species meat. It has led to slaughter of a great number of poultry and production of a huge quantum of poultry slaughterhouse by-products consequently resulting in hazardous environmental pollution problems. Utilization of these poultry slaughter house by-products into a value added pet food has been attempted. Hence, the study on the development of low cost pet food from poultry slaughterhouse by-product meal was carried out by using simple easily adoptable technique.

Materials and Method

Preparation of pet food

Ingredients: Dogs are omnivorous and have lower protein requirements than cats. Therefore, formulations for dogs are more flexible and may include more vegetable proteins. Vegetable proteins typically have highest protein-to-ash ratios and contain some fiber. Soybean meal is an excellent source of amino acids lysine and tryptophan. However because dogs prefer animal tissues to vegetable meals. It is advantageous to add animal source proteins to the formulation. A blend of animal tissue meals and vegetable meals is appropriate and often optimal [5].

Poultry by-product meal (head and feet) prepared from simple cooking process were used for incorporation in the pet food formulation. The other ingredients like corn, rice, calcium carbonate, dry yeast, beef fat were purchased from local market. The corn and rice were finely ground before incorporation. Vitamin and mineral mixtures were purchased from local market.

Pet food formulation: Based on the nutrient specifications and recommendations given by the AAFCO and NRC for the adult dog’s maintenance diet, the pet food was formulated incorporating the prepared poultry slaughterhouse by-product meal and cruciferous vegetable waste meal as given below (Table 1) [6,7].

| Ingredient | Percentage | Grams |

|---|---|---|

| White corn flour | 10 | 100 |

| Wheat glutean meal | 10 | 100 |

| Rice flour | 20 | 200 |

| Chicken head meal | 20 | 200 |

| Chicken feet meal | 15 | 150 |

| Beef fat | 10 | 100 |

| Cruciferous vegetable meal | 10 | 100 |

| Calcium carbonate | 2 | 20 |

| Dry yeast | 2 | 20 |

| Iodised salt | 0.5 | 5 |

| Vitamin & Mineral mix | 0.5 | 5 |

| Total | 100 | 1000 g |

Table 1: Nutrient specifications and recommendations given by the AAFCO.

Mixing of ingredients and pre conditioning

Before cooking all the ingredients were mixed thoroughly and water was added gradually in 1:1 ratio during cooking.

Cooking procedure: Wet semisolid dough was prepared by adding the various ingredients one after the other and steam cooked at 121°C temperature and 15 lbs pressure for 15 minutes. The cooked semi dry dough (70°C) was extruded through a mechanical hand extruder to prepare pet food. The same was dried in hot air oven at 70°C for 18 hrs, to prepare a brownish meaty flavored pet food.

Six trials were conducted and the prepared pet food was subjected to various quality parameters like nutrient composition, physico-chemical characteristics, shelf-life parameters and acceptability by pets.

Proximate analysis: Proximate composition viz., moisture, total ash, crude fiber, crude protein, ether extract, nitrogen free extract were analyzed as per AOAC [8]. Ether extract estimation was done in SOCS plus (Model SCS 4, Pelican Equipment Pvt. Ltd., Chennai) and crude protein estimation in KEL plus (Model Classic DX, Pelican Equipment Pvt. Ltd., Chennai), Metabolisable energy was estimated as per the procedure of NRC [7]. Amino acid analyses was done in Agilent 1100 HP-HPLC, USA and Chemstation software was used, Fatty acid analyses was done in Gas Liquid Chromatography, Mineral analyses was done in (ICPOES) (Perkin Elmer Optima 5300 DV Model).

Storage studies

Physico-chemical changes

TBA (Thio-barbituric acid number): Thio-barbituric acid number was determined by the procedure outlined by Strange et al. with slight modification. Twenty gram of sample was blended in a mixer with 50 ml of cold 20% trichloro-acetic acid (TCA) for 2 minutes [8]. The blended contents were rinsed with 50 ml of distilled water, mixed together and filtered through the filter paper (Whatman No.l, 18.5 cm diameter) and the filtrate was collected in a 100 ml capacity measuring cylinder. The filtrate, termed the TCA extract was used in the estimation of thio-barbituric acid number (TBA) and Tyrosine value (TV). Test solution was prepared by mixing 5 ml of TCA extract with 5 ml of TBA reagent. Blank solution was prepared by mixing 5 ml of 10% TCA with 5 ml of TBA reagent. Both blank and test solution were kept in boiling water bath for 30 minutes and cooled in running tap water. The colour development was measured as absorbance at 532 nm in a UV-VIS Spectrophotometer (ELICO systems, Bangalore) at medium sensitivity.

Tyrosine value (TV): Tyrosine value was determined by the modified method of Strange et al. two and a half millilitre (2.5 ml) of TCA extract was diluted with equal quantity of distilled water in a test tube. To this 10 ml of 0.5 N NaOH was added followed by 3 ml of diluted folin coicalteau’s phenol reagent (1 part folin ciocalteau’s phenol reagent with 2 parts distilled water) [9]. After mixing and keeping for 15 minutes at room temperature the developed colour was measured as absorbance at 660 nm in a spectrophotometer (SL – 164, double beam UV – VIS spectrophotometer, ELICO India Ltd., Hyderabad) at low sensitivity, using a blank containing 5 ml of 5% trichloroacetic acid (TCA) with 10 ml of 0.5 N sodium hydroxide (NaOH) and 3 ml of diluted folin ciocalteau’s phenol reagent. By reference to the standard graph, the tyrosine value was calculated as mg of tyrosine/100 g of sample.

Microbial analysis: Sample for microbial count was prepared by taking five gram of sample aseptically and homogenized with 45 ml of 0.1% sterile peptone water, in a stomacher to obtain an initial dilution of 10-1. Serial ten-fold dilutions were made up to 10-6 in pre-sterilized tubes containing 9 ml of 0.1% peptone water. The sample preparation and plating were carried out under laminar air flow. Total viable count and yeast and mould counts of processed samples were determined by the method described by American Public Health Association (APHA) using media from Hi-Media, Mumbai [10].

Preparation of questionnaire: The response of the pet dog and owner’s observations were recorded through a questionnaire prepared in English and as per the guidelines of Ponmani and Karthikeyan, karthik et al. with slight modifications [11-14].

The parameters like appearance, consistency and odour were given the highest score of 9 and the least score of 1. Response of the pet to the product was given the highest score of 3 and the least score of 1. Preference of the product on subsequent times were given 1, 0 scores. Influence of the product on digestion and food intake were given 0, 1 scores respectively.

Statistical Analysis

The data obtained were analyzed statistically in SPSS software (version 20.0) as per the standard procedure of Snedecor and Cochran.

Results and Discussion

Proximate composition on ‘0’ day was the values for the moisture (4.57), crude protein (25.41), ether extract (17.68), crude fibre (1.32), total ash (9.82), Nitrogen free extract (45.77%) and ME (420.15) kcal/kg as feed basis respectively. Protein is the most expensive macronutrient in both economic and ecological terms, it is arguably the nutrient requiring the most attention as it pertains to sustainability. Pet food professionals need not only consider the total amount of protein to target, but also the quality, bioavailability, and ingredient source as well. A unique issue in the pet food industry is the large disconnect between the protein requirements of dogs and cats and the crude protein (CP) concentration present in the average pet food.

According to the NRC, CP minimal requirement of adult dogs and cats is 8% [dry matter basis (DMB)] and 16%, respectively. The NRC also provides a recommended allowance (RA) of 10% and 20% CP for adult dogs and cats, respectively. The RA is often used because it accounts for differences in nutrient bioavailability among ingredients and genetic variation among animals. The recommendations made by AAFCO for adult dogs (18% CP) and cats (26% CP) were also established to account for these differences [7,15].

Elliott et al and Boari et al, stated that High-protein, lowcarbohydrate foods elicit lower glycemic responses compared with those containing high concentrations of carbohydrate, which can benefit dogs with insulin resistance or diabetes. Furthermore, studies have shown that foods with a higher protein content (103 g/1000 kcal, or ∼31% for a 3000 kcal/kg diet), in addition to higher fiber content, decrease voluntary intake, increase the amount and rate of weight loss, and increase fat mass loss during weight loss in dogs [16,17].

Diez et al. and Blanchard et al. stated that dog foods containing high protein and low energy maintain muscle mass during weight loss [18,19].

Reynolds et al. reported that additionally, high-protein diets can be beneficial for endurance exercise in dogs. Sled dogs fed a diet consisting of 35% of energy from protein had higher plasma volume than dogs fed a diet with 18% of energy from protein [20].

Higher fat content was noticed which is due to addition of beef fat and chicken feet and head in product preparation. Fats are highly desirable ingredients in dog and cat foods with concentrated energy (about 3 kcal/g), palatability enhancement and a high digestibility of 95-98%. Precise minimum dietary fat requirements for dogs and cats have not been determined. With high palatability desired for pet foods, increased fat provides more fatty acids than are needed for requirements but enhances palatability in all good pet food.

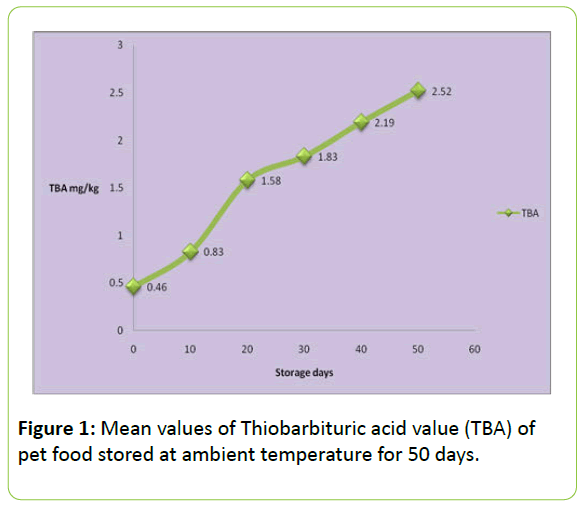

The TBA (thiobarbituric acid) values expressed as mg malonaldehyde/kg increased significantly (P<0.01) from 0.46 to 2.52 mg/kg during the room temperature storage up to 50 days indicated in Figure 1. The values are in agreement with the results of Karthik et al. [14]. They also stated that the pet food prepared by incorporation of 20% spent hen meal and stored for a period of 45 days in room temperature revealed significantly higher TBA values expressed as mg malonaldehyde/kg from 0.41 mg to 2.52 mg/kg during the storage period.

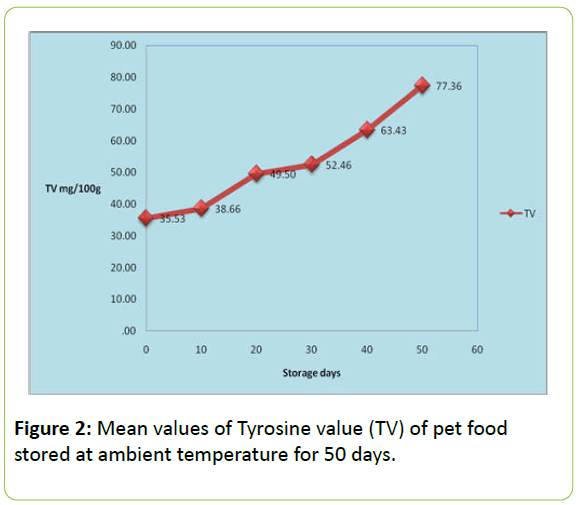

The tyrosine value expressed as mg/100 g increased significantly (P<0.01) from 35.53 to 77.36 mg/100 g during the room temperature storage up to 50 days indicated in Figure 2. The results were in agreement with that of Rajkumar et al. who concluded that the mean tyrosine value of the samples packed in aerobic, vacuum and modified atmosphere increased gradually from the day of packaging up to 21st day of storage. Karthik et al., reported that the tyrosine values expressed as mg/100 g increased significantly (P<0.01) from 42.42 mg to 76.00 mg/100 g during the storage period [14,21].

The total viable count expressed as log value increased significantly (P< 0.01) from log 3.46 to 5.90 CFU/ gram during the room temperature storage up to 50 days. The results were in agreement with the results. The steady increase in microbial count indicated the post processing/handling contamination, in agreement with the results of (Fischer et al., 2007) reported that even if dry extruded pet food was poor substrate for microbial development, the need for hygienic practice is essential and it cannot be ignored [22].

Amino acid profile of the developed pet food contains aspartic acid, glutamic acid, serine, histidine, glycine, threonine, alanine, arginine, tyrosine, valine, methionine, and phenylalanine. isoleucine, leucine and lysine levels 9.71, 16.32, 5.18, 9.87, 7.93, 5.83, 9.94, 4.13, 0.71, 1.19, 5.80, 5.93, 3.77, 7.64 and 6.04 in percentage basis respectively and showed in Table 2. The results are in agreement with the normal range of recommended level of nutritive requirements of dog by NRC. Since protein content in poultry by-product is relatively very high and the low cost at which these poultry by-product can be procured and also its ability in controlling environmental pollution its makes poultry by products a better choice to prepare pet food over other sources [7].

| Composition | % basis |

|---|---|

| Aspartic acid | 9.72 |

| Glutamic acid | 16.32 |

| Serine | 5.18 |

| Histidine | 9.87 |

| Glycine | 7.93 |

| Threonine | 5.83 |

| Alanine | 9.94 |

| Arginine | 4.13 |

| Tyrosine | 0.71 |

| Valine | 1.19 |

| Methionine | 5.8 |

| Phenylalanine | 5.93 |

| Isoleucine | 3.77 |

| Leucine | 7.64 |

| Lysine | 6.04 |

Table 2: Amino acid profile of pet food.

Methionine and cysteine are sulphur amino acids that are important for the synthesis of the hair protein, keratin. The keratin synthesis needed to maintain skin and hair can account for up to 30% of an adult dog’s daily protein requirement. Lysine is often the first limiting amino acid in the diet, and sensitive to heat during pet food processing it undergoes a chemical reaction with sugar (Maillard reaction), thought to be essential for synthesis of all proteins.

Phenylalanine and tyrosine are aromatic amino acids that are vital for the production of pheomelanins (yellow to red pigments) and eumelanin (brown to black pigments) that define the colour of an animal’s coat and also production of thyroid hormones and other key metabolites as well as being vital for tyrosine synthesis.

Besides its role in hair and iris pigmentation, tyrosine was also a dopamine, noradrenalin and adrenalin precursor. These molecules are required for the proper functioning of the brain and in reproduction. Leucine, isoleucine and valine stimulate the synthesis of proteins and slow their breakdown in the muscles. The effectiveness of these amino acids helps to increase lean mass and prevent muscle wasting.

Fatty acids are required for a number of processes in the body including maintenance of a healthy skin and coat, a strong immune system and reproductive function. Fatty acid profile of the developed pet food contains myristic acid, palmitic acid, stearic acid, behenic acid, palmitoleic acid, oleic acid, ecosapentaenoic acid, docosahexaenoic acid, linolenic acid, linoleic acid, and arachidonic acid are 2.903, 25.06, 14.32, 0.71, 7.63, 36.32, 0.26, 0.22, 0.53, 7.01 and 7.57% respectively and showed in Table 3. The results were congruent with the standards of AAFCO recommendations [15]. The minimum nutritive requirement of adult dog for growth and reproduction for linolenic acid is 1%. NRC recommendation for daily allowance of nutritive requirement of linoleic acid, alpha linolenic acid, Eicosapentaenoic+docosahexaenoic acid for adult dogs is 2.8, 0.11 and 0.11% respectively. Essential fatty acids must be provided in a pet’s diet because they cannot be synthesized by a dog in sufficient amounts. Fatty acids are required for a number of processes in the body including maintenance of a healthy skin and coat, a strong immune system and reproductive function. A deficiency of essential fatty acids may result in reduced growth or increased skin problems. Omega-6 fatty acids are essential for healthy reproduction since they are involved in the synthesis of prostaglandins. Prostaglandins are hormone-like compounds that regulate a number of reproductive processes including ovulation and parturition. Linoleic acid is an essential fatty acid for dogs. The results obtained in the study were in agreement with the normal range of recommended level of nutritive requirements of dog prescribed by NRC [7].

| Fatty acids | Percentage |

|---|---|

| Saturated fatty acid | |

| Myristic acid | 2.903 |

| Palmitic acid | 25.06 |

| Stearic acid | 14.32 |

| Behenic acid | 0.71 |

| TOTAL | 42.993 |

| Monounsaturated fatty acid | |

| Palmitoleic acid | 7.63 |

| Oleic acid | 36.32 |

| Total | 39.95 |

| Polyunsaturated fatty acid omega-3 | |

| EPA | 0.26 |

| DHA | 0.22 |

| Linolenic acid | 0.53 |

| Total | 1.01 |

| Omega-6 | |

| Linoleic acid | 7.01 |

| Arachidic acid | 7.57 |

| Total | 14.58 |

Table 3: Fatty acid profile of pet food.

Mineral profile of prepared pet food contains calcium, phosphorus, potassium, sodium, copper, iron, manganese; zinc values are 2.4, 0, 0, 0.1, 0.3, 0.0, 0.0 and 1.3 g/100 g of feed respectively and showed in Table 4. According to AAFCO the level of mineral requirement such as calcium and phosphorus in pet food for dogs were 2.5 and 1.6 percentage respectively [6]. According to NRC maximum range of calcium, phosphorus, potassium, sodium, copper, iron, manganese, zinc were 1g, 0.75 g, 1 g, 200 g, 1.5 g, 7.5 mg, 1.2 mg and 15 mg respectively. The results are in congruent with the normal range of recommended level of nutritive requirement values for dogs by NRC. Calcium plays two fundamental roles in the body. Over 90% of calcium found in the body retained in the bones and teeth where, along with phosphorus, it was responsible for making these structures rigid. Calcium also plays a role in transfer of information between the cells and in the transmission of nerve impulses. Phosphorus was a structural component of DNA and RNA, the molecules that carry the cell’s genetic code. Zinc was essential for the transport of vitamin A in the blood and plays an important role in reproduction. It was also crucial for collagen and keratin synthesis and fundamental element involved in skin and coat health, and wound healing. Since mineral content in poultry by product was relatively very high and low cost at which these poultry by-product can be procured and also its ability in controlling environmental pollution its makes poultry by products a better choice to prepare pet food over other sources [7].

| Major elements | g/100g of feed samples |

|---|---|

| Calcium | 2.4 |

| Copper | 0 |

| Potassium | 0 |

| Magnesium | 0.1 |

| Sodium | 0.3 |

| Zinc | 0 |

| Iron | 0 |

| Phosphorus | 1.3 |

Table 4: Mineral profile of pet food.

According to Lindsay Beaton quoted that there are several ways the palatability segment of the pet food industry was responding to this pet-owner relationship shift, from contributing to marketing claims that satisfy consumer demand to exploring new technologies and new areas of study that might help shed light on the complexities of pet palatability preferences. Pet owner’s opinion on the quality of developed pet food was recorded through a score card (9 point hedonic scale) was given in Table 5. The given pet food was readily accepted by the pet dogs and no digestive disturbance or allergic reactions were noticed due to feeding of the developed pet food. The mean values of the scores given for Appearance, consistency, odour and overall acceptability were 6.60+0.19, 5.07+0.21, 6.07+0.33 and 6.67+0.35 respectively and indicated in Table 5.

| Parameters | Pet food |

|---|---|

| Appearance * | 6.60 ± 0.19 |

| Consistency * | 5.07 ± 0.21 |

| Odour* | 6.07 ± 0.33 |

| Pet’s acceptability ** | 6,67 ± 0.35 |

Table 5: Mean ± S.E. Color, consistency, odour and pet’s acceptability score of pet food conclusion.

Karthik et al. concluded that a pet food (whole meal) with good nutritive quality and palatability to dogs can be prepared by incorporating 10%-20% of spent hen meal which can be safely stored up to 45 days at room temperature [14].

Hence it could be concluded that a pet food with good acceptability to dogs can be prepared by incorporating 35% and 10% of poultry by product meal viz chicken head and feet and cruciferous vegetable by-product meal can be prepared using minimum low cost equipment and simple easily adoptable technique.

The production cost of pet food prepared by incorporating 35% poultry by-product meal and 10% cruciferous vegetable byproduct meal was Rs.70/kg. The cost of commercially available pet food (whole meal) based on the market survey, ranged between Rs.160 to 550/kg depending upon the ingredient added. Hence, it can be concluded that the pet food (whole meal) developed by incorporating 35% poultry by-product meal and 10% cruciferous vegetable by-product meal in the present study have a good scope for market potential.

Hence, the manufacture and marketing of the pet food can be undertaken by any entrepreneur without much capital investment, thereby providing self-employment opportunities to women self-help groups, unemployed rural youth, school drop outs, etc [23,24].

References

- Mountney GJ (1976) Poultry by-products technology. (2ndedn), The Avi publishing company, inc, Westport.

- Aldrich G (2006) Rendered products in pet food: Essential rendering all about the animal by-products industry. National Renderers Association, irby lithographic company, Inc. Arlington, Virginia.

- Najafabadi HJ, Moghaddam HN, Pourreza J, Shahroudi EF, Golian A (2007) Determination of chemical composition, mineral contents and protein quality of poultry by-product meal. Int J PoultSci 6: 875-882.

- Ockerman HW, Hansen CL (1988). In Animal By-products processing. Ellis Horwood limited, Chichester, England.

- Cowell CS, Stout NP, Brinkmann MF, Moser EA, Crane SW (2000) Making commercial pet foods. (4thedn), Small Animal Clinical Nutrition, Mark Morris Institute, Topeca, Kansas, USA.

- AAFCO (2008) Official publication of the Association of American Feed Control Officials. Inc, Atlanta.

- National Research Council (2006) The nutrient requirements of dogs and cats. National Academic press, Washington, USA.

- AOAC (1995) Official Methods of Analysis. (16thedn), Association of Official Analytical Chemist, Int, Arlington VA.

- Strange ED, Benedict RC, Smith JC, Swift CE (1977) Evaluation of rapid tests for monitoring alterations in meat during storage. J Food Prot 40: 843-844.

- Speck ML (1984) Compendium of methods for the microbiological examination of foods. (2ndedn), American Public Health Association, Washington DC.

- Ponmani V (1997) Studies on the preparation of dog chew and evaluation of its shelf-life. Thesis submitted to Tamil Nadu Veterinary and Animal Sciences University (M.V.Sc.), Chennai.

- Karthikeyan N (2000) Processing, packing and shelf-life evaluation of pet food from poultry by-products. Thesis submitted to the Indian Veterinary Research Institute (M.V.Sc.), Deemed University, Izatnagar.

- Karthikeyan N (2004) Effect of processing methods on nutritional quality and storage stability of poultry by-product meal based pet foods. Thesis submitted to the Indian Veterinary Research Institute (Ph.D), Deemed University, Izatnagar.

- Karthik P, Kulkarni VV, Siva KK (2010) Preparation, storage stability and palatability of spent hen meal based pet food. Journal of Meat Science 47: 330-334.

- AAFCO (2008) Official publication of the Association of American Feed Control Officials. Inc, Atlanta.

- Elliott KF, Rand JS, Fleeman LM, Morton JM, Litster AL, et al. (2006) A low carbohydrate, high protein, moderate fat and fiber diet reduces postprandial glucose concentrations compared with a traditionally recommended canine diabetes diet and an adult maintenance diet in healthy dogs. J Vet Intern Med 20: 1508–1514.

- Boari A, Aste G, Rocconi F, Dalessandri A, Vita S (2008) Glargine insulin and high-protein-low-carbohydrate diet in cats with diabetes mellitus. Vet Res Commun 32: S243–S245.

- Diez M, Nguyen P, Jeusette I, Devois C, Istasse L, et al. (2002) Weight loss in obese dogs: Evaluation of a high-protein, low-carbohydrate diet. J Nutr 132: 1685S–1687S.

- Blanchard G, Nguyen P, Gayet C, Leriche I, Siliart B, et al. (2004) Rapid weight loss with a high-protein low-energy diet allows the recovery of ideal body composition and insulin sensitivity in obese dogs. J Nutr 134: 2148S–2150S.

- Reynolds AJ, Reinhart GA, Carey DP, Simmerman DA, Frank DA, et al. (1999) Effect of protein intake during training on biochemical and performance variables in sled dogs. Am J Vet Res 60: 789–795.

- Raj VK, Babu RN, Dushyanthan K, Ezhivelan S, Venkataramanujam V (2007) Heritage Indian meat products. Processed Food Industry 11: 43-49.

- Fischer AR, De Jong AE, Van Asselt ED, De Jonge R, Frewer LJ, et al. (2007) Food safety in the domestic environment: An interdisciplinary investigation of microbial hazards during food preparation. Risk Anal 27: 1065-1082.

- https://www.petfoodindustry.com/articles/5937-why-pet-food- palatability-trends-

- Torres CL, Hickenbottom SJ, Rogers QR (2003). Palatability affects the percentage of metabolizable energy as protein selected by adult beagles. J Nutr 133: 3516–22.

Open Access Journals

- Aquaculture & Veterinary Science

- Chemistry & Chemical Sciences

- Clinical Sciences

- Engineering

- General Science

- Genetics & Molecular Biology

- Health Care & Nursing

- Immunology & Microbiology

- Materials Science

- Mathematics & Physics

- Medical Sciences

- Neurology & Psychiatry

- Oncology & Cancer Science

- Pharmaceutical Sciences